Our Ultimate Scroll Saw Buying Guide

For people who are buying a scroll saw for the first time, understanding what you need in your new saw can be overwhelming with the huge range of features and types.

Nowadays scroll saws are perfect for delicate design work and extremely safe to use in the workshop, but when choosing your model you have to consider its size, throat length, power and speed as well as many other extra features to make sure that you saw is right for you.

To make your search for the right scroll saw a little easier, we have composed an extensive buying guide below which will cover everything from the basic features a scroll saw has to the most essential specs to look for in your model.

So without further chatting, let's get into it!

What Is a Scroll Saw Used For?

Before we get into how scroll saws work and what you need in your tool, let's go over the purpose of these saws and what you can use them for to make sure the device is suited to your workshop tasks.

A scroll saw is one of the smaller power tools and is mostly used for detailed woodworking projects where you need to make dovetail joints or tiny carving for decor, they are best for these cuts on woods thanks to their thinner blades.

How Does a Scroll Saw Work?

To understand what you need in your scroll saw, you have to know how these saws operate with their different parts to achieve cuts in wood.

We have listed the basic parts of a scroll saw below and how they work.

Table

The table of a scroll saw is what you hold your material on while cutting, it makes cuts on wood more accurate and is typically made out of either aluminium or metal material.

Tables often have different throat sizes on these machines which determines the size of the piece of wood that you can cut as well as a tilting angle which will indicate the range of angled cuts and bevel edge cuts you can make in wood.

Blade

The blade is one of the most important parts of a scroll saw, they come in a pinned and pinless type but vary according to factors such as teeth and thickness.

We will go over the two main types below.

- Pinned blades - These types of blades are held in place on the scroll saw via pins, they are one of the oldest pin-end blades too. To change pine-end blades you simply have to remove and release the hook, making them easy to replace in case of blade breakage.

- Pinless blades - This choice of blade type needs to be threaded through the type of wood you are working on and put through the slots which are below and above the table of the scroll saw. The type of blade has to be tightened at both ends to make sure it is secure.

Arm

For cutting intricate design this is where the arm of the scroll saw comes into action, it holds the blade and acts as the connection between the motor of the saw and pieces of wood to cut.

Figuring out which arm to have on your scroll saw can be a little confusing as they come in three different types, we will list them down below to see how they differ.

- C Arm Scroll Arm - This type of scroll saw c-arm type arm has one pivot point which allows the blade of the machine to move up and down in an arc-like movement, they are one of the best arms to choose on your machine if you are looking to cut heavier duty blocks of wood.

- Parallel type - A parallel arm of a scroll saw has two pivot points with two arms that meet in the middle, this allows the blade of the scroll saw to move in a reciprocating up and down motion.

- Parallel linked - For people who want little vibration when using their scroll saw, a newer parallel linked arm is a great choice. This parallel linked arm has one arm up and down but is shorter than a normal parallel linked arm.

Air Blower

Air blowers on scroll saws are very important as these machines create a lot of sawdust during cutting would, most scroll saws have this a tube and it can be connected to a dust port to carry the sawdust further away.

Blade Tensioner

The blade tensioner of a scroll saw refers to the knob on the machine which allows you to easily adjust how tight or lose the blade is of your saw. This is needed according to the project you are working on, too tight or too loose could ruin your project.

What Type Of Scroll Saw Blade Do I Need?

When looking for your new scroll saw, one of the most important factors to consider is the blade which comes in pinless and pinned types as we discussed above.

Scroll saw blades however also come in different sizes and materials which we will go into further detail about below.

Blade Size

The blade sized for scroll saw vary between sizes of 0-12, the higher the number is of your blade then the thicker it will be and the fewer teeth it will have.

Blade Teeth

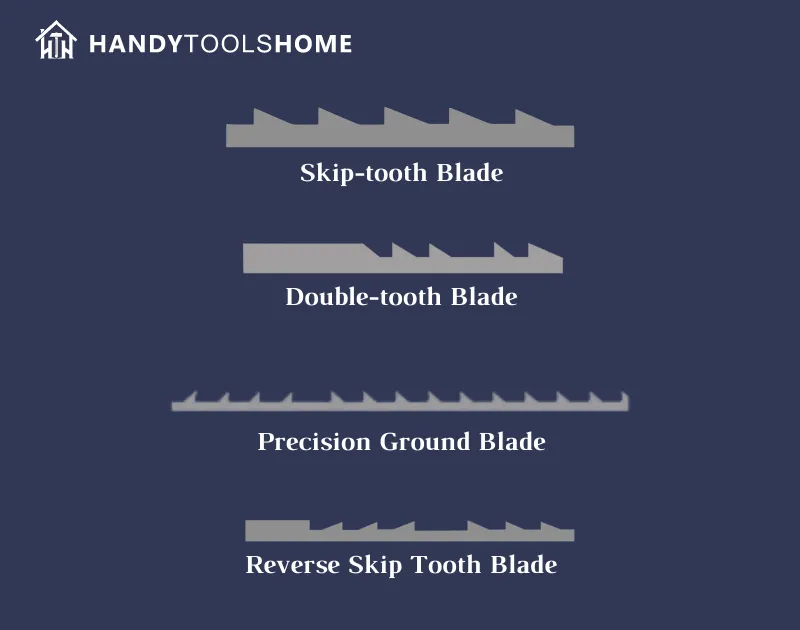

Blade teeth vary according to the type that you buy, they come in eight different standard types which we will list below.

- Standard blades - These forms of blades are the most common for scroll saws and typically have standard space teeth, they are mostly made of metal but can come in different special materials.

- Skip-tooth blades - Skip-tooth blades are accurate blades for beginners thanks to their larger spacing in between teeth which allow you to cut patterns in wood much slower.

- Reverse-tooth blades - For avoiding splinters in softer wood, reverse-tooth blades are often the best choice. These blades have teeth on top with a similar design to skip-tooth blades except feature teeth on the bottom as well as the top to stop splintering.

- Double-tooth blades - Double-tooth blades have a space on every third tooth to make slower cuts and are perfect for larger woodworking projects as they do not heat up fast.

- Precision-ground blades - The teeth of these blades are very small and are grounded to be extremely sharp so as they can cut material smoothly.

- Crown-tooth blades - Crown-tooth blades have teeth shaped like crowns, they are designed to be in pairs and have one tooth facing up while the other one is facing down. This allows you to cut in a direction and you can simply use the tooth in the other direction when one starts to get blunt.

- Spiral blades - These spiral blades have teeth in all directions, hence the spiral name, they are best used for starting a rough cut but not for detailed designs in wood.

Different Cuts To Make With a Scroll Saw

If you are not sure whether or not a scroll saw is worth the investment then you are probably unsure about whether you need one for the type of cutting work you will be doing.

We have listed the different kinds of material scrolls saws can cut below as well as the various cuts they can make to see if it's worth it for your woodworking.

Types Of Material

Scroll saws are mostly of use for woodwork hobbyists who need to make designs in wood but they can be used to cut a variety of materials as long as you have the right kind of blade.

- Metal.

- Leather.

- Aluminium.

- Rubber.

- Fibreglass.

- Ceramic tiles.

Types Of Cuts

- Angled cuts.

- Plunge cuts.

- Dovetail joints.

- Thick cuts.

- Curved cuts.

Top Features To Consider In a Scroll Saw

If you want to get the best scroll saw for your money then you should make sure it has some of the essential specs as well as additional features to get the most value out of it when woodworking.

To help you out with your search we have listed the most important features for you to be considering in your brand new scroll saw down below.

- Size - The main feature to consider in models of scroll saws are its size as this ultimately determines the size of the workpiece you will be able to cut. You should consider the durability of the table on your saw too and check if it tilts for making angled cuts in woodwork.

- Power - Since your scroll saw is has a motor for the power you should consider the kind of power you need, this will be measured in watts and it will also affect the speed of your device. The higher the power the harder materials you can cut.

- Speed - Check the strokes per minute your scroll saw has as this will indicate its speed, a high amount of strokes per minute is better for harder wood, you should ensure this is a variable speed motor too for more control and accuracy when cutting different materials.

- Throat length - The throat length of your scroll saw is important as it affects the size of the wood you can cut at once, it refers to the distance between the saw blade and the back of the saw. Most throat sizes in types of scroll saw designs range between a measurement of 16-20 inches, you should look for a throat size of around 18-inches on your scroll saw to allow for versatile use.

- Blade type - As we mentioned above in a buying guide, scroll saws come with a variety of blade types which are pinned or pinless, pinless tend to be the better more modern choice nowadays as they are good for delicate cutting, however, pin-end blades are much easier to switch out.

- Depth of cut - The depth of cut your saw has should be at least 50mm, however some scroll saws do have a larger depth cut for larger woodworking projects.

- Blade tension adjustment - Depending on your design in the scroll saw they will come with different ways for blade tension adjustment. Make sure your tension adjustment is easy to use via either a lever or button, it should be toolless too for quick adjustment time.

- LED work light - Having an LED work light on your saw can be useful for keeping the accuracy of your cuts in low light situations, another extra to look out for on your saw are foot switches as they allow you to remove your hands from the machine.

- Vibration - It is important to watch out for the vibration of your scroll saw, you want to avoid too much vibration as it causes a lot of noise and can decrease the accuracy of your work.

- Warranty - Always ensure that your scroll saw has a warranty of at least one year or more for buyers protection against faulty models.

Tips For Using a Scroll Saw

Once you've chosen your best scroll saw it's important you know the best way to use it, not only to protect yourself but also to get the most out of your tool.

We put together a list below which includes some of the essential safety tips for using your saw as well as some cutting tips during.

Safety Tips

- Sand your wood before cutting - Sanding your wood before cutting is safer and will result in a quicker cutting time.

- Wear safety gear - Make sure you are wearing the correct safety gear before starting to cut, goggles for example are essential as it stops sawdust from going into your eyes.

- Never rush - It's never a good idea to try and force your work through a scroll saw, instead let the blade do its job, you should never rush larger workpieces as it can overheat or worse even bend your blade which is dangerous.

- Check the blade of damage - Before cutting with your scrolls saws blade you should take a little time to check how the blade is beforehand, a damaged blade should never be used for cutting wood and the same goes for a dull blade.

- Keep your table at the right height - Your scroll saws table should always be around mid-torso length for the best accuracy.

- Use good lighting - Always make sure you are using your scroll saw in good lighting so as you can see what you are doing properly, an additional LED work light can help if your workshop is poorly lit.

Cutting Tips

- Check the blade tension - You have to ensure your blade tension is adjusted properly before cutting, if it is too loose then it won't cut anything but too tight can also damage the blade.

- Use dry wood - If your wood gets wet is a safety hazard and can ruin the quality of your material.

- Drill a hole - One way to prevent your work splitting is by drilling a hole in the material beforehand, placing a scrap piece of wood below and voila!

- Lubricate your blade - Using some WD-40 on your blade will improve its performance and help it to last longer.

Frequently Asked Questions About Buying a Scroll Saw

How much is a scroll saw?

Scrolls often have an affordable price of around £100-£150 however price ranges up to £300 if you want a more high quality larger scroll saw.

What is the difference between a scroll saw and a band saw?

Bandsaws are often used for cutting a larger thickness of material while scrolls saws purpose is for small detailed work in wood.

How many teeth should my scroll saw blade have?

This depends on the type of material you will be cutting with your scroll saw, some have a higher amount of teeth but most have around 6-80 for the standard cutting of wood.

Can I cut metal with a scroll saw?

Softer metal can be cut with a scroll saw but you should avoid cutting heavy metal, you also have to ensure you are using the right kind of metal cutting blade to avoid damage to your saw and ensure an accurate cut.

Which kind of throat size do I need on a scroll saw?

A 16-inch or 18-inch throat size is great for your scroll size however you can get 20-inch throat models for cutting even larger woodworking pieces.

How do I stop excessive vibrations from my scroll saw?

Scrolls saws are known to vibrate a fair amount when cutting, one way to reduce this is by adding weight to the saw to keep it stable, this could be sandbags for example.

Final Words

Overall, buying the best scroll saw is simple as long as you consider the most essential features such as its size, blade and speed. Make sure you are matching the features of your scroll saw according to what you will be using it for and always ensure you are following safety tips during cutting.