Our Guide To Choosing The Right Scroll Saw Blade

Even if you buy the best scroll saw on the market, the blade you are using it with will determine the quality and finish of your cut, which makes choosing the right one crucial to ensure a high-quality finish on your woodwork.

The scroll saw blade you use depends on multiple factors such as the type of material you are cutting and the kind of cut that you want to make. For example, thicker wood requires a larger size of scroll saw blade.

To help you through the blade choosing process, we have composed an extensive scroll saw blade buying guide below which cover everything you need to know about selecting the correct, as well as a high-quality scroll, saw blade.

How To Choose a High-Quality Scroll Saw Blade

Since scroll saw blades come in so many different types you need to make sure you are selecting high-quality saws to get the best finish on your work, one way to ensure this is by choosing a high-quality brand, cheap blade types should be avoided.

The quality of your saw blades depends on many factors but it mostly comes down to the manufacturing process of the blades, we have listed the two most common types of blade manufacturing processes for scroll saw blades down below.

- Ground hardened steel blades - These types of blades are the most popular choice for scroll saws as they last a long time plus ensure smooth cutting on a variety of materials due to the manufacturing process. The stone-ground type of blade allows you to have a sharp blade that leaves a cut without the need to sand or correct.

- Milled scroll saw blades - Milled scroll saw blades go through a process called metal flow which is where the regular blade is hardened by heating it then tempering the metal. These blades cut similar to grounded blades.

Factors Affecting Your Scroll Saw Blade Choice

There are a few different factors that can influence the kind of scroll saw blade you choose, some to mention are -

- Material - A proper blade choice needs to be made according to the kind of material that you are cutting, there are different scroll saw blades according to if you are cutting metal or wood as well as hardwood or softwood. Thicker material will also need a larger blade.

- Kind of cut - The kinds of the blade that you choose will differ according to the type of cut that you are making too. For rough cuts in dense wood, you can use a larger blade, but for making small angled cuts you need a smaller type of blade to ensure accuracy.

- Price - Your budget determines whether you get a premium blade for your money or low-quality blades, the more you spend then the better quality blade you will get.

- Pattern - The smaller the size of the blade for patterns the better as it gives you more accuracy and control.

Which Blade Size Do I Choose?

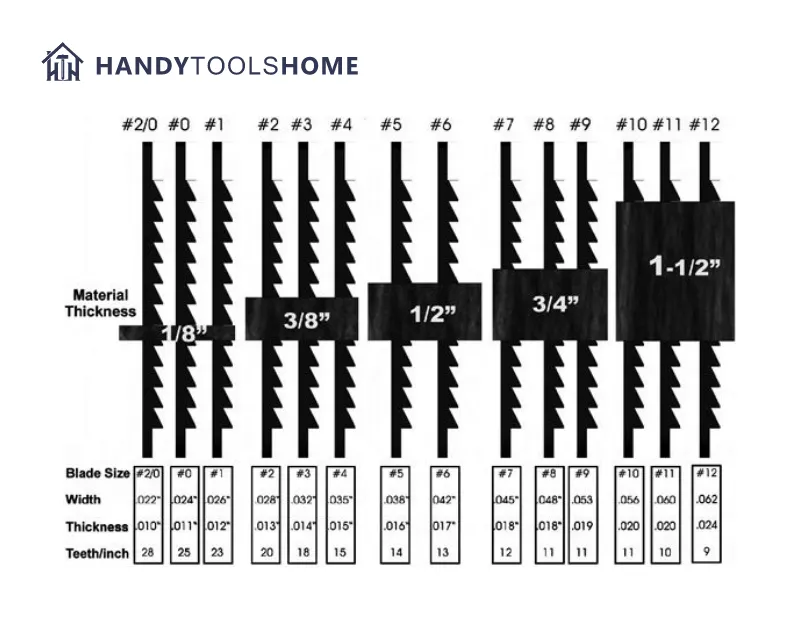

The selection of blades for scroll saws also differ in size and the number of teeth they have, your choice of blade size is once against influenced by the material and kind of cut you are making.

- Sized blades - There is no actual measurement for scroll saw blades when it comes to size, but a standard blade size range is often indicated by numbers ranging between 2-12, the larger number indicating a standard blade that is thicker and wider with fewer teeth.

- Teeth per inch & gullet - This refers to the number of teeth your metal blades have which indicates the kind of cut it can produce, it is also shortened as TPI. The gullet indicates the amount of space in between each tooth.

Different Types Of Scroll Saw Blade

You can determine the size of your blade and its teeth by choosing the right type of scroll saw blade which comes in eight different types.

However, before we get into further detail about the different types of scroll saw blade type it is important to know whether you are choosing a pin-end blades type or a plain-end blades type.

- Pin-end blades - These variety of blades are secure to your scroll saw via a small pin and hook making them much harder to change.

- Plain-end blades - Most scroll saws use a plain end blade type as they are easier to change, they are secured onto the scroll saw with a clamp at the top and bottom of the table.

Our Guide To Scroll Saw Blade Types

Since you will most likely be using a plain-end blade configuration with your scroll saw, we can dive into looking at the different types in our blade selection guide below.

Standard Tooth Blades

Standard tooth blades normally come in both a metal and wood design, they have an even number of teeth with equal spacing all facing in the right direction. They typically come in a standard five-inch-length blade size which will be either size 2 or 3.

We would recommend using this type of saw blade for softer materials up to around 3/4 an inch thick.

Reverse-Tooth Blades

Reverse-tooth blades cut in a downside direction and are similar to skip-tooth blade types except they have half of their blades facing up in the other direction. This allows you to cut in a reciprocating motion both up and down.

This type of reverse skip-tooth blade is perfect for cutting thinner materials such as plywood due to the number of teeth.

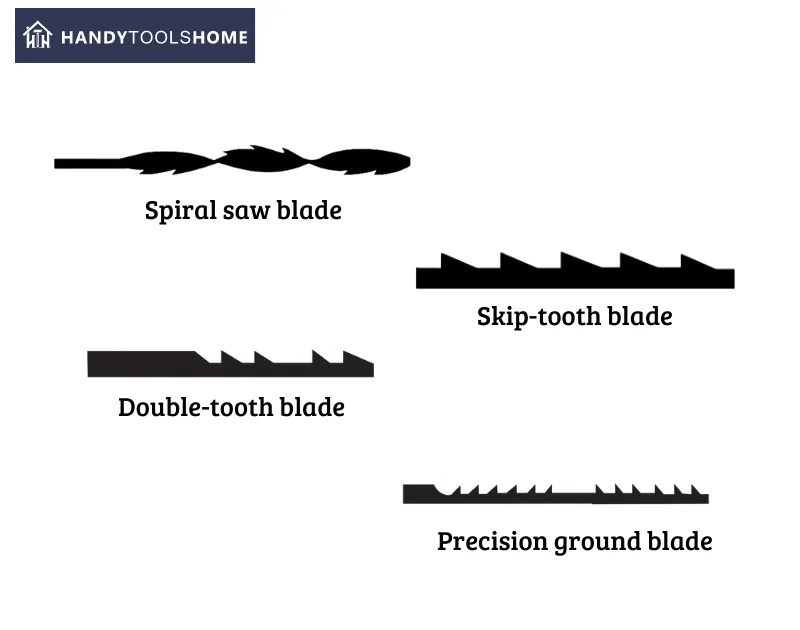

Double-Tooth Blades

Double-tooth blades have a space after every pair of teeth and are designed to be similar to a standard-tooth blade. The design of these blades allows for a very smooth and slow cut which is good for accuracy on all kinds of material but is often much harder to control due to the set-up of the teeth.

Skip-Tooth Blade

A skip tooth blade has a space in between every tooth, they all face in the same direction like a standard scroll saw blade which allows for ease of sawdust removal and is perfect for beginners.

We would only recommend using a regular skip-tooth blade for rough cuts of wood due to their lack of teeth, they are much harder to control if you want to achieve small delicate designs.

Crown-Tooth Blades

Crown-tooth blades have each of their tooth facing in a different direction which creates a crown shape type look to the blade teeth. They are best used for cutting plastic-type materials but have the disadvantage of collecting a lot of sawdust when they are used to cut wood.

Spiral Blades

Spiral blades for scroll saws can be twisted in any kind of direction to achieve a cutting edge as they have teeth on all sides in all directions! Although these allow you to pull your material through in any direction for cutting they lack accuracy and do tend to wander.

Precision Ground Blades

Precision ground kinds of blades are much thinner than your standard blade size making them the best choice for detailed woodwork, they do take some experience to control, however.

Tips For Using & Selecting Scroll Saw Blades

Finding the right kind of scroll saw can be a little overwhelming with the large range of the market from different blade manufacturers, we have bullet-pointed some of our best tips to help with your selection and use down below.

- Use a larger blade for thicker wood - Ordinary blades will not cut it when cutting through woods such as cherry or walnut, in this case, you need a larger blade with a size of either 5 or 7 sizes of the blade for this solid-surface material.

- Smaller blades are best for softwood - Thin wood such as plywood or veneer need a small blade to prevent damage or splintering while cutting. The higher the amount of teeth of your small blade has the slower it will cut through the material.

- A thicker blade will last you longer - For cutting thicker materials, a blade size of 9-12 will be sufficient, they will last you a very long time because of the fewer teeth and are perfect for durability.

- Buy blades in bulk - It's a good idea to have a lot of scrolls saw blades on hand, not only do these blades break easily but you also don't know when you are going to need different types of metal blades for materials, having extra blades on hand can save the day.

- Check your pattern - No matter whether you are cutting hardwood or softwood, you need a blade that is small for this job so as you can have more control over your pattern when cutting.

- Measure the stack - If you are stack cutting wood then measure the total depth of the cut from the whole stack, not individual pieces, this will guide you in you making the right blade size choice. For example, if you have a stack of 1-inch pieces then you would need a scroll saw which is number 5 or 7 to be able to cut through it.

- Oil your blades - Adding a small drop of lubrication such as coconut oil on your blade can stop it from overheating, this happens because scroll saws operate at a very fast speed when cutting.

- Choose a high-quality blade - You can find the cheapest blade types on the market for your scroll saw, but they will often dull quickly meaning they need replacing more often, costing you even more money in the long run. It's best to always spend a little more and choose a high-quality blade for better performance.

- Change when dull - Dull blades overheat quickly and can produce a very poor cut on your work, it is best to change your saw blades often to avoid this from happening and keep them sharp when they start to get dull.

A Step By Step To Install Your Scroll Saw Blade

Once you have chosen the right scroll saw blade for the kind of work you will be cutting, you must know how to install and set one up properly on your machine.

We have put together a short step by step down below to help you out with first time installation.

- First of all for safety unplug your scroll saw and put on some safety gloves to protect your hands during the blade change.

- Check the clamps which come with your saw blade and make sure they are in good condition, if yours needs an Allen key for fitting choose one of the right sizes.

- Take one end of your blade and guide it through the opening on the clamp which is between two hex screws and make sure the teeth are in the right direction. Tighten each hex screw to make sure it is secure.

- Make sure the bald is running straight down between the clamps then repeat on the other side and secure the clamps with a half rotation once again.

- Find the inner hook for clamping the blade underneath your saw's table and place the arm into the hook then hook it up to the upper clamp holder too and adjust with the blade tensioner system until desired.

- Turn your switch back on and allow the saw to run a little then turn off and adjust the tension of the blade once again, it always becomes a little loose after first-time use.

Frequently Asked Questions About Scroll Saw Blades

How much do scroll saw blades cost?

The cost of these wood blades vary, but by the rule of thumb you can expect to spend around £10 on them for a high-quality pack of blades, this price can go up and down according to the type, however.

What type of materials can you cut with a scroll saw blade?

Primarily scroll saw blades are used for cutting wood however you can also find special blades for cutting metal, plastic, plexiglass, rubber, leather or even brass and copper.

How often should I change the saw blade on my scroll saw?

Scroll saw wood blades get dull pretty fast, the amount you change these blades depends on how often you are using, how long for and the hardness of the project material. On average you expect to replace standard and special blades after around 30 minutes of use.

Which scroll saw blades should I get as a beginner?

The best type of scroll saw blade as a beginner are skip-tooth blades, these blades due to their design often force you to cut much slower which helps to improve accuracy.

Are there any safety tips for working with scroll saw blades?

Always ensure that you are not using a broken blade to cut with, ensure the tensioning of the blade is right and make sure you are wearing appropriate safety equipment such as googles during the cutting process.

Last Words

To conclude, the scroll saw blade you use depends on what you will be cutting and the type of cut you are making, for thicker materials, use a larger blade, and for smaller materials with detailed design use a small blade with small teeth.

Always make sure that your blade is set up properly in the machine for it to be working properly and safely.