With so many different kinds of saw out there, it can be difficult to know which type to get. Table saws, circular saws – what’s the difference? What are they each used for? Which should I buy?

At this point, it might seem like some kind of Saw Wars situation but when it comes down to it, table saws and circular saws offer some different services and advantages so there are a few important factors to consider. What you end up buying will depend entirely on what kind of work you need to do.

Without further ado, let’s get into dissecting the differences between the two so you can make an informed decision on which one you need!

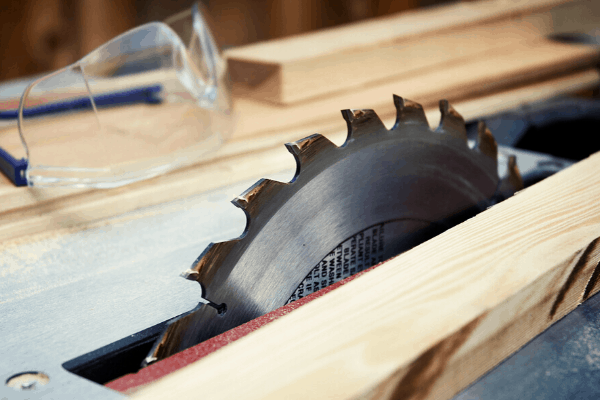

What is a Table Saw?

At its basest level, a table saw is a tool used in woodworking and carpentry. As the name suggests, it is also a saw (but you didn’t need me to tell you that). Unlike some other kinds of saws such as the handsaws that we’re used to seeing in movies and balancing in our granddads’ garden sheds, table saws have a bit more to them in terms of assembly.

A table saw is an example of a mounted saw.

(image of a table saw here)

The key components of a table saw are the blade, table-top, and motor although their make-up is quite complex, and many smaller parts are integral to their structure. The blade on a table saw is circular and is mounted to the table with only a small section appearing above the surface of the table.

Another important feature on a table saw is the arbor which is essentially a lever for raising and lowering the height of the blade to allow you to cut thicker pieces of wood as required.

Because table saws make use of a motor for spinning the blade, they’re more powerful and efficient than using a handsaw for a similar job. The table itself normally has several different built-in tools for measuring which can help you to cut wood to more precise specifications.

Although this isn’t necessarily a standard feature, most table saws nowadays also come with safety systems for detecting fingers and the like, helping to ensure the user’s safety whilst sawing.

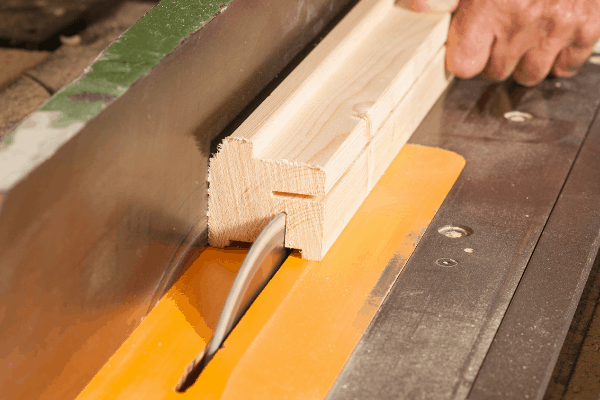

What Kinds of Jobs are Table Saws Used For?

If you have a large amount of wood to get through and you want to do so with precision and as quickly as possible, then a table saw is your guy! Table saws are the ideal tool for many different tasks, some of which include:

- Cross-Cutting – a common cut that simply consists of cutting against the grain of a piece of wood.

- Miter Cuts – any angled cut apart from 90° angles.

- Ripping – a type of cut that entails taking a large or wide piece of wood and cutting it lengthways to make several smaller pieces of often the same dimensions as one another.

The key thing with all of these cuts is that they involve straight lines. Table saws are great at cutting straight lines. This makes them the ideal tool companion for woodworkers and DIYers alike.

Are There Any Suitable Alternatives?

Although a table saw is going to be the optimal tool for certain kinds of job, in a pinch, you could probably get by using some of these alternatives.

- Jigsaw – capable of cross-cutting wood, although the finish will be more jagged than the precision result of a table saw.

- Miter Saw – as the name suggests, this kind of saw is specifically designed for miter cuts so in actuality, is probably a better option than a table saw for this kind of cut!

- Bandsaw – while the table saw is the optimal choice for ripping, a bandsaw will do the job, albeit leaving rougher edges.

While it’s not impossible to get on with your woodworking jobs without a table saw, for many kinds of work, the table saw is unparalleled.

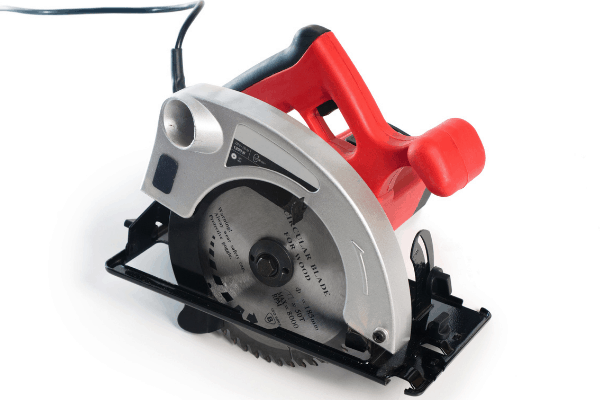

What is a Circular Saw?

A circular saw is similar to a table saw in one very important aspect: the blade is circular (bet you didn’t see that one coming), as is a table saw’s. A circular saw is another example of a power saw, and like the table saw described above, it is a fairly complex tool when placed next to other, simpler saws. When compared with the table saw however, the circular saw is a bit simpler in composition.

Circular saws are hand-held as opposed to table saws which are mounted.

The basic make-up of a circular saw consists of an arbor and the blade itself (sometimes instead of a blade, circular saws come with a toothed or otherwise abrasive disc). There are other design features and functional components that will vary from model to model but the blade and arbor are the main defining features.

Circular saws can be built specifically to cut different materials including wood, stone, metals and plastic, depending on the type of blade or disc used. Circular saws are also portable which is a handy advantage when compared with the more stationary table saw.

In terms of safety features, the most prominent and important one is the blade guard which is exactly what is sounds like: it will guard you from the blade. It’s easy to get distracted, even when doing potentially dangerous tasks, and the blade guard is there to make sure accidents don’t happen.

Circular saws are generally more affordable than some other kinds of saws and they’re also highly versatile.

What Kinds of Jobs are Circular Saws Used For?

The circular saw’s versatility is one of its most useful advantages and they are capable of carrying out many tasks in both construction and DIY contexts. The circular saw is typically capable of making the same kinds of cuts as a table saw with a couple of differences:

- Cross-Cutting – circular saws are also able to make cross-cuts although they might leave a slightly more rugged edge than a table saw, and they’re also a bit more difficult to keep exactly straight.

- Miter Cuts – circular saws are capable of making decent miter cuts, however due to the angling of the blade for these types of cuts, it can be tricky to keep the blade exactly where you want it (that’s not to say it’s impossible though!).

- Ripping – circular saws can rip, but make sure you steady the saw so as to keep the lines as straight and even as possible.

- Bevel Cuts – similar to miter cuts but bevel cuts are relative to the face of the material being cut whereas miter cuts are relative to the square side of the material being cut. A circular saw can make bevel cuts whereas it would be very difficult to do so with a table saw.

One of the key differences between the table saw and circular saw in terms of cutting capability is control; it is easier to control where a table saw cuts than where a circular saw cuts.

Are There Any Suitable Alternatives?

The alternatives to a circular saw will depend on what outcome you’re looking to achieve and there is quite a bit of overlap with the table saw as they share many functions.

- Handsaw or jigsaw – can be used for ripping and cross-cutting, although the finish might be slightly less even.

- Miter Saw – can be used for miter cuts, and just as a miter saw is better at miter cuts than a table saw, it is also better than a circular saw.

- Trim Saw – a smaller, more compact version of a circular saw which is often easier to handle due to its lesser stature and weight.

As you can see, there is a lot of overlap between different saws, and indeed between circular saws and table saws.

To Conclude

Multi-functional tools are always going to be more useful than tools only capable of carrying out one specific task. Both table saws and circular saws are multifunctional and so either will make an excellent DIY or carpentry companion.

If it’s a case of choosing between the two, then you need to weigh up what kind of work you mainly find yourself doing, what your budget is (circular saws are more affordable than table saws),and where you’re going to be doing your work. If you’re looking for a saw to help you with your carpentry hobby or your DIY needs, then a table saw is probably ideal, however a portable circular saw is going to be more convenient if you work in different locations.

If you take enough time to think about it, do some research, and talk to some professionals, you’re going to be happy with whatever saw you bring home. And who knows, you might be able to grab one of each, building a nice little collection for all occasions!