Our Troubleshooting Guide To Why Your Circular Saw Keeps Stopping

Even though a circular saw is one of the toughest power tools on the marker for carpentry, this doesn't mean they don't run into problems that can lead the circular saw blade to stop spinning.

Most of the time, a circular saw will keep stopping due to a blade problem, this could mean that the blade is damaged or you are using dull blades, another popular reason can be a motor issue inside of the saw, this could be the motor arbor or brass giving you problems.

We have listed some more common reasons as to why your circular saw blade might keep stopping below to help you get to the root of this issue as well as some solutions on how to fix your circular saw to get it up and running again.

Common Factors As To Why Your Circular Saw Keeps Stopping

Apart from a blade problem or a motor issue, there are a number of other common reasons as to why your circular saw might having running issues that you need to troubleshoot in order to fix the power tool, we have listed these reasons below to help you identify which one you might be having.

It's The Blade

Let's start with the most common reason as to why your saw keeps stopping, the blade.

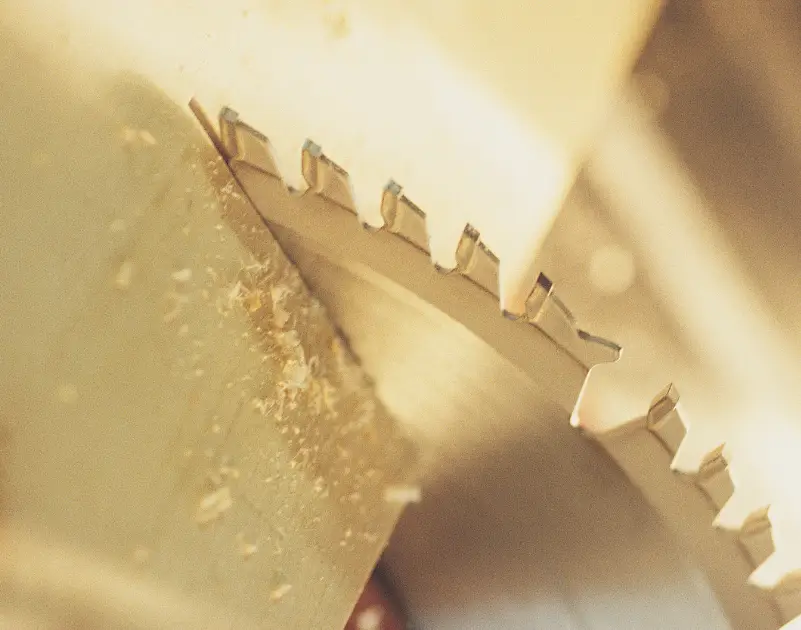

It is important to use a sharp quality blade on your circular saw, a bad blade that is dull will inevitably keep getting stuck in a piece of wood, as well as unsharpened blades stopping your circular saw, you should check if the blade is damaged too as this cause the machine to stop.

Motor Problem

A damaged motor may also cause your circular saw to stop spinning, most brushless motors need the motor brass and motor arbor to be working properly in order for the whole motor to function right, the motor might stop due to the malfunctioning of blades too.

Power Issues

There are a few different power issues that might be causing your circular saw to halt, the first could be that the circular saw does not have enough power for the material that you are trying to cut, it is important to consider the power cord too, check it is not loosely connected to the saw and that the cord or extension cord is not damaged.

Using the saw for long periods or forcefully can also cause the overheating of blades which will cut out the machine for safety protection.

Loose Bolts

If you have a loose clutch or bolts where your blades meet the saw arbor then this blade arbor bolt might be to blame for your circular saw to keep stopping. This can cause a faulty blade that stops while the brushless motor continues to run during cutting.

Pinching The Blade

Trying to cut a piece of wood that is supported from both ends can cause pinching of the blade on your saw, causing it to stop, the blade adhering to the workpiece is a safety measure so nothing to worry about.

The Workpiece

Lastly, another reason as to why your circular saw might not be working how it should be could be down to using an improper work piece. Any workpiece which is not supported properly on your saw, too thick for the depth of your saw capacity or has knots could cause your machine to cut out.

To avoid using an improper work piece always check your stock thoroughly beforehand.

Dust

Dust build-up in your machine can be a common reason for the motor to stop working, it can also cause your saw to overheat too.

How To Fix a Circular Saw Which Keeps Stopping

Now we have been over and troubleshot the most common reasons as to why your circular saw keeps stopping, we can now get into how to fix these problems so as you can get your saw working back to how it should be.

Replace The Power Cords

If there are signs that your power cord is damaged then you need to make sure you replace it as soon as possible, replacing is the better solution than trying to repair it in this case, check the power outlet too.

Change The Blades

One way to help fix the issues of blades on your circular is by replacing them with high-quality new blades, also make sure you use the right-sized blade on your circular saw, an oversized blade will stop the machine from cutting properly.

As well as cleaning the blades you should also try to tighten any bolts of the clutch too as these loose bolts can cause the blade to malfunction.

Clean It Well & Grease

Change the grease oil on your motor frequently to stop it from building up, use a good lubricant like WD-40 to lubricate your blades after use and clean any dust with a blower from the motor.

Use It On a Slow Speed

To avoid overheating on your circular saw try to use it at the lowest speed you can and give it breaks when you sense the saw overheating, this will prevent it from cutting out during use.

Check The Motor & Replace Damaged Parts

Your circular saws motor consists of the motor brass and motor arbor, you should check that both of these motor parts have not worn out, if so you would need to replace the parts to make the powerful motor work again.

Our Best Tips For Maintaining Your Circular Saw

Just like any woodworking tool, you need to make sure you are doing proper maintenance for your circular saw in order for it be functioning properly and last long term.

We have put together a few of our best tips for maintaining your circular saw below to keep it in the best condition possible.

- Clean and sharpen the blades - Rust and other substances can build up over time on your saw blade and cause damage, so cleaning it regularly as part of maintenance is essential with a brass brush. You should be sharpening your blades often to ensure they don’t become dull too.

- Test the lower guard - The lower guard on your circular saw is important for user protection so you should be making sure that the guard can raise and lower easily with no obstruction to the movement.

- Wipe it down - After every use, it’s a good idea to wipe your saw down, stay clear of the blade and use a cloth with damp water for this job, don’t get any liquid on the power tool.

- Air vents - The air vents are an important part of your circular saw as they make sure the device cools down properly, this can get clogged with sawdust over time so you should make sure to blow it with compressed air to loosen any debris now and then.

- Check the housing - Inspect the outer housing of your saw for any cracks or damage before use, check the handle is working fine too as this is what you use to guide stock through when cutting. The same goes for gears and moving parts on the device.

Frequently Asked Questions About Circular Saws & Stopping Issues

What happens if my motor gear grease has solidified?

When motor grease oil is left too long and not switched out in your saw it can solidify and cause eventual running issues, you can solve this easily by putting new high-quality grease instead.

Is binding bad on a circular saw?

Binding happens on a circular saw when the machine is not set to proper cutting depth, it can also happen when your material is supported from two ends and is not free to fall, this is bad as it can stop the flow of your saw when cutting.

When should I sharpen the blades of my circular saw?

Knowing when to sharpen your circular saw blades will come down to how often you use the machine and the material that you use it on, typically, during a blade's lifespan you will end up sharpening it 3-4 times, but this could also be when you feel as if it is getting dull or cutting through material slower than normal.

Why can I smell burning from my circular saw?

If you can smell burning from your saw then it could possibly be from overheating, this might be down to cutting tough material or cutting at too high of a speed, you should check the blades and motor too so as you can identify where the smell is coming from and inspect.

Last Words

To conclude, if your circular saw keeps cutting out during work then you probably have a faulty motor or dull/damaged blades, luckily, most of these parts can be replaced easily and your circular saw should go back to functioning as normal.

Always keep your saw clean and try to maintain it as well as you can to avoid running into these power issues.